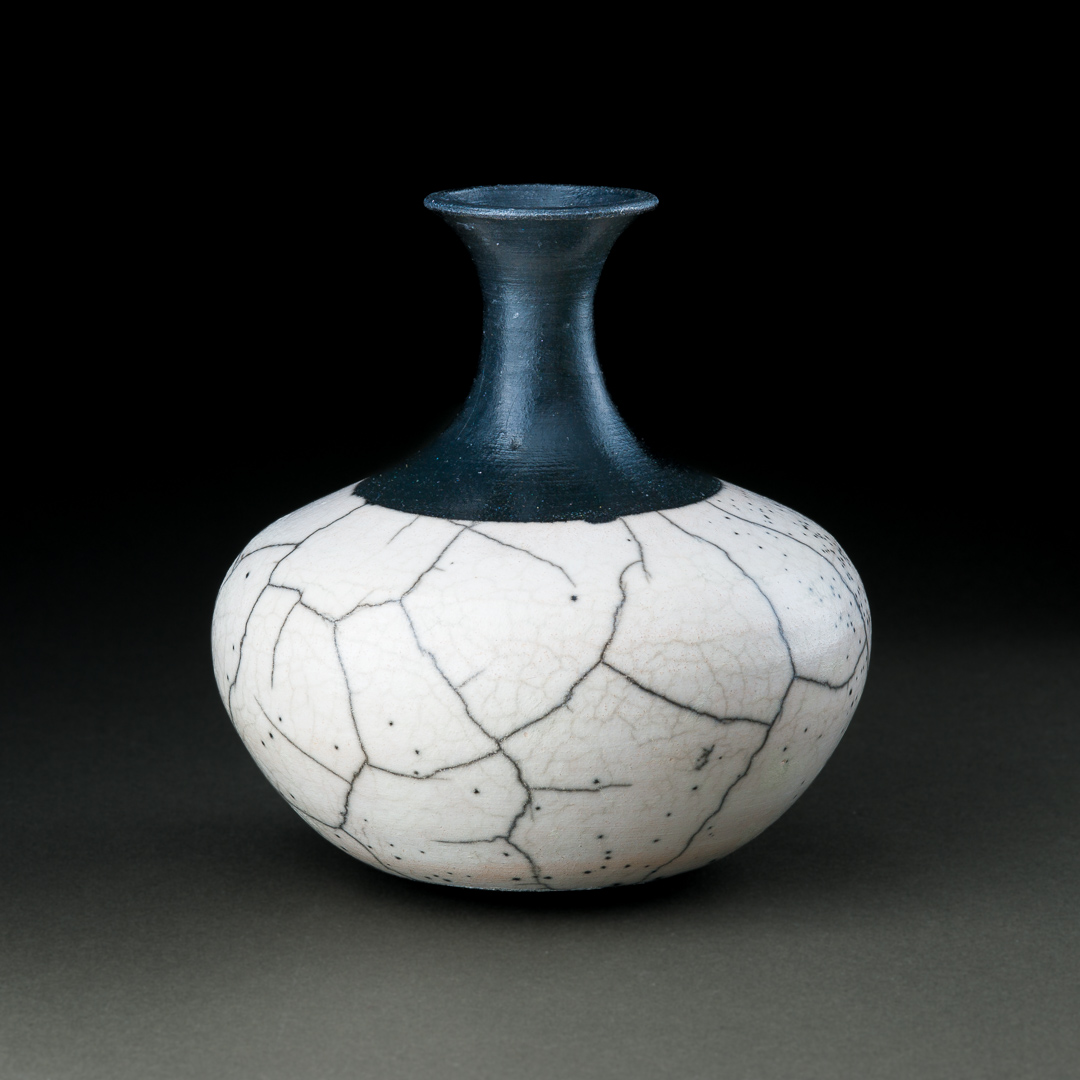

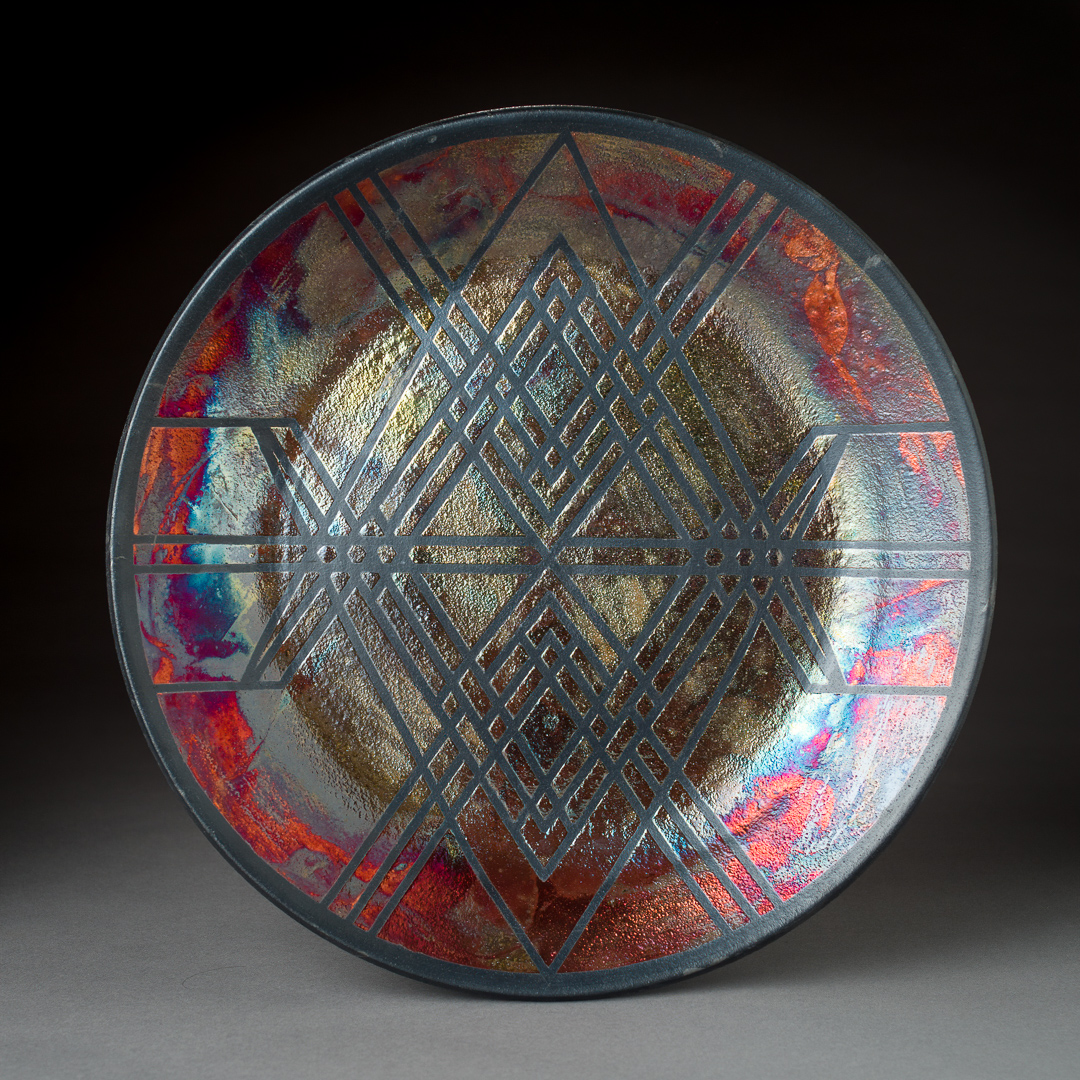

Creating raku pieces begins the same way as making conventional stoneware: throwing on the wheel, possibly carving a pattern, bisque firing, taping and glazing. The type of clay used can withstand the extreme temperature changes in the dramatic firing process. The piece is heated quickly to around 1800° F in a home-made heat-blanket-lined garbage can kiln heated with a propane burner. The piece is then removed and quickly placed in a reduction chamber (newspaper-lined garbage can) where the hot piece immediately ignites the reduction material. A lid is quickly and tightly clamped on the chamber causing the flames to immediately burn all the available oxygen. The chemical reaction causes often-beautiful colors and textures to magically appear. And sometimes not—we’re at the mercy of the kiln gods.